The Rohm Printhead KA2004 – BG59 has the following advantages:

High – resolution Printing1: The KA2004 – BG59 printhead supports a resolution of 203dpi/300dpi, which can meet the needs of high – definition printing and ensure clear and sharp printing quality, whether it is used for printing barcodes, text or graphics.

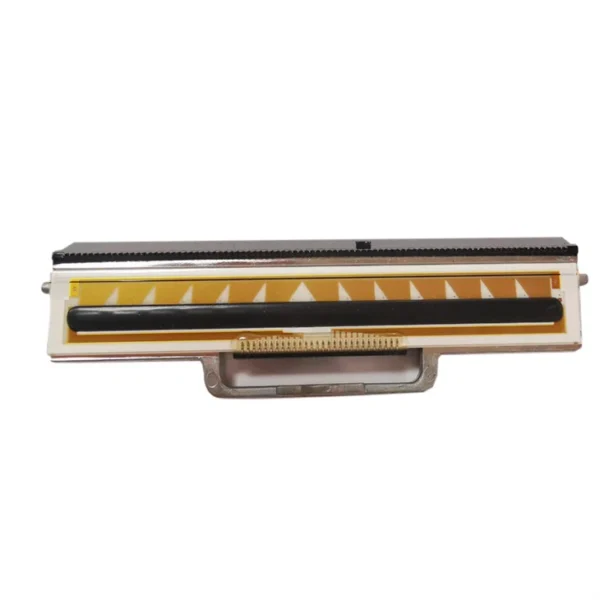

Dual – mode Printing: It supports both thermal and thermal – transfer printing modes, providing versatility for different printing applications. It can work with a variety of thermal – sensitive materials, such as thermal paper and thermal – transfer ribbons, to meet the needs of different users for printing materials and media.

Low – power Consumption: By optimizing the heating – element structure and improving the layout of the driver IC and wiring, the KA2004 – BG59 achieves 7.2V drive. Compared with the previous 12V – drive printheads, the applied energy required for printing is reduced by about 66% under the condition of a printing speed of 50mm/s. This helps to save energy and is especially suitable for portable devices with limited power supply, such as portable A4 printers, prolonging the battery life of the device.

Uniform Heating: The printhead adjusts the individual wiring of the heating elements to make the heat generation more uniform, thus stabilizing the printing quality. Even under the condition of a high printing speed of 100mm/s, it can still achieve clear printing quality at a resolution of 203dpi, ensuring that there are no obvious differences in color and clarity in different parts of the printed matter.

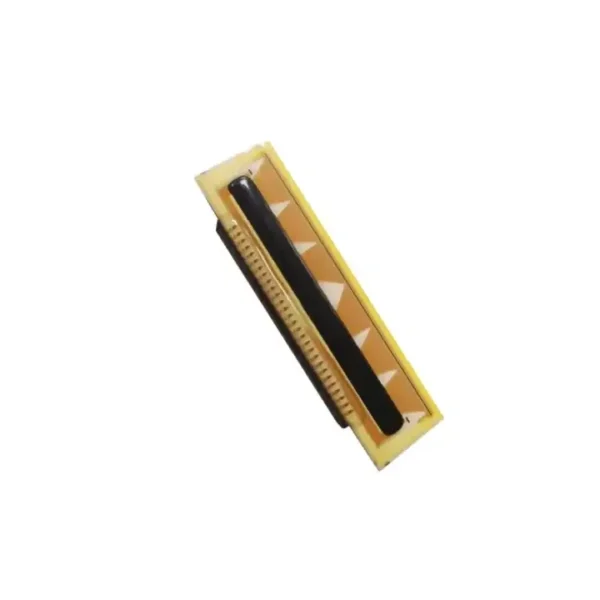

Compact Structure: With a longitudinal width of only 11.67mm, which is about 16% narrower than the previous 14mm, it helps to save space in the overall printer design. This compact design is beneficial for integrating into portable or space – limited printing equipment without sacrificing performance.

High Durability: Its structural design can reduce the influence of expansion and contraction caused by temperature changes, improving mechanical strength and durability. This makes it suitable for high – frequency use in harsh environments, reducing the frequency of printhead replacement and maintenance costs, and is suitable for various industrial – grade and commercial – grade applications.

High Design Flexibility: Usually, thermal – print heads are used with connectors and heat sinks, but the KA2004 – BG59 can be provided in the form of a single – ceramic substrate, which helps to improve the flexibility of printer design. Designers can more freely choose and design the installation position, connection mode and heat – dissipation mode of the printhead according to the specific needs of the product, so as to better meet the personalized needs of different printer products.